In June 2025, Tesla quietly paused production of its Optimus humanoid robot—just months after Elon Musk promised thousands would be built by year’s end.

The reason? A cocktail of technical failures: overheating joints, underpowered batteries, fragile gear systems. Instead of rushing flawed machines to market, Tesla hit pause. And in that decision lies the real story.

This article breaks down the core issues, Tesla’s redesign plan, and what’s really at stake for the future of humanoid robotics.

Why Tesla Paused Optimus Production

According to DIGITIMES and other supply chain sources, Tesla halted Optimus parts procurement in mid-June 2025, after assembling around 1,000–1,200 units.

The reason? Hardware that didn’t scale:

- Joint motors overheated under extended load.

- Transmissions wore out quickly, raising durability concerns.

- Battery life was insufficient for sustained, real-world deployment.

- Gripping hands lacked precision and payload strength — prompting tests of three new hand designs.

The production pause is expected to last ~2 months, allowing engineers to recalibrate before any mass rollout.

“Most humanoid robots rely on proprietary, non-standardized components. That drives up cost — and technical risk.” — DIGITIMES Asia

Inside the Optimus Gen‑3 Redesign

Despite setbacks, Tesla is not retreating — it’s refining. The Optimus Gen‑3 model showcases significant technical leaps:

- 22 degrees of freedom in the hands — 5 fingers with 4 joints each, plus 2 wrist joints.

- A forearm-based actuator system for better balance and precision.

- Tendon-and-ball-screw transmissions designed to mimic organic movement.

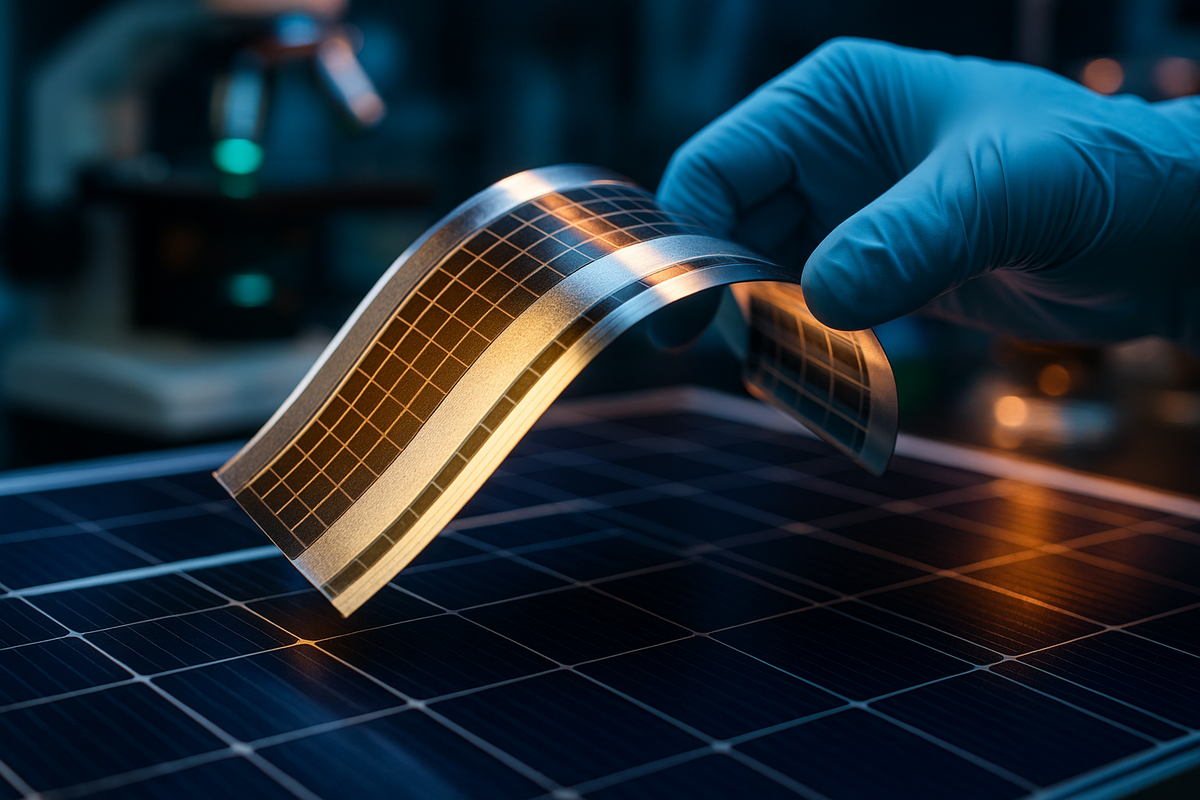

But these upgrades come at a cost: added weight and complexity. Tesla is now exploring lighter materials to offset design bloat, while also assessing multiple hand technologies for better dexterity.

Leadership Change: A Strategic Inflection Point?

Right as the redesign kicked off, Milan Kovac, Tesla’s head of Optimus engineering, stepped down, citing family reasons. His successor? Ashok Elluswamy, Tesla’s AI lead and former head of Autopilot software (Reuters).

This leadership handoff hints at a strategic realignment — possibly shifting Optimus toward more AI-centric functions, driven by software rather than just mechanical muscle.

Tesla insiders suggest Elluswamy is pushing for tighter integration of Grok, Tesla’s in-house chatbot, to enable natural language interaction.

External Factors: Rare Earths and Global Constraints

Beyond internal flaws, Optimus also faced geopolitical headwinds. Earlier in 2025, China restricted exports of rare-earth magnets — critical to the robot’s actuators. Tesla’s negotiations for export licenses are still ongoing.

And even inside Tesla factories, Optimus performance hasn’t wowed:

- Current prototypes operate at less than 50% efficiency compared to human workers, limited to tasks like battery transport (AINVEST).

Is the 2025 Target Dead?

Elon Musk’s original goal: 10,000 Optimus units by year-end. Reality: paused production, ongoing redesign, and underwhelming internal performance.

Instead, Tesla plans to debut the refined Gen‑3 version at its upcoming shareholder meeting. With integrated voice interaction powered by Grok and updated limb architecture, this version could reset expectations.

But the 2025 goal? It's gone. A 2026–2027 commercial release now seems more likely.

Conclusion: Reset, Not Retreat

Tesla’s Optimus isn’t a failure — yet. The redesign marks a necessary shift from overpromise to engineering rigor. Building a humanoid robot that can perform real-world labor isn’t just hard — it’s one of the greatest technical challenges of our era.

The next Optimus version will need to prove not only capability but consistency. A robot that can grip, walk, and work — not just pose or pour wine on stage.

"Vision without execution is hallucination. Tesla is now in the phase where only execution matters."